Senior Lean Practitioner Certification

Lean the skills to coach others through the problem solving process

THIS CERTIFICATION Will help you

- Effectively coach others

- Engage people in problem solving

- Achieve higher levels of performance

- Develop more problem solvers

“Before attending, my biggest problem was getting buy in and applying lean tools throughout our plant. Now I know how to ask the right questions, and listen for what is happening. I’ll apply the learnings from today by asking the right questions, and not beginning with the solution already in mind, but by getting the right facts using a scientific approach to solving problems. ”

Page Townsend, CI Leader

“In this certification, you will learn to coach others through the problem-solving process consequently helping your whole team make improvements. This will transform your company from one that starts and stops improvement programs to one where continuous improvement is part of the culture.”

Kirby Sneen, President, Manufacturers Alliance

THIS CERTIFICATION INCLUDES

6 EXPERIENTIAL WORKSHOPS + A PROJECT & COACHING

Managing for Daily Improvement

It is not easy to make the transition from making improvements yourself to helping others solve problems. But, seeing your team sustain higher levels of performance makes it worth it. In this experiential workshop you will learn how to systematically develop the tools and resources needed to support your team in making improvements daily.

Course Objectives:

- Define the Sr. Lean Practitioner Model

- Interpret performance indicators to determine gaps and trends

- Learn how team huddles provide shared understanding & action

- Demonstrate understanding of Leaders Standard Work

- Identify the purpose and types of Gemba Walks

- Practice coaching to develop problem solvers

Leaders Standard Work

People that transform traditional manufacturing processes to a lean production system require a new kind of leader. They need a leader that is willing to consistently provide the coaching and resources needed to solve problems and prevent cultural barriers from popping up. In this experiential workshop you will learn to become that leader.

Course Objectives:

- Define the Sr. Lean Practitioner Model

- Develop leaders standard work for all levels of the organization

- Ensure the standard is followed daily and improved regularly

- What it should cover

- Pros and cons of different formats

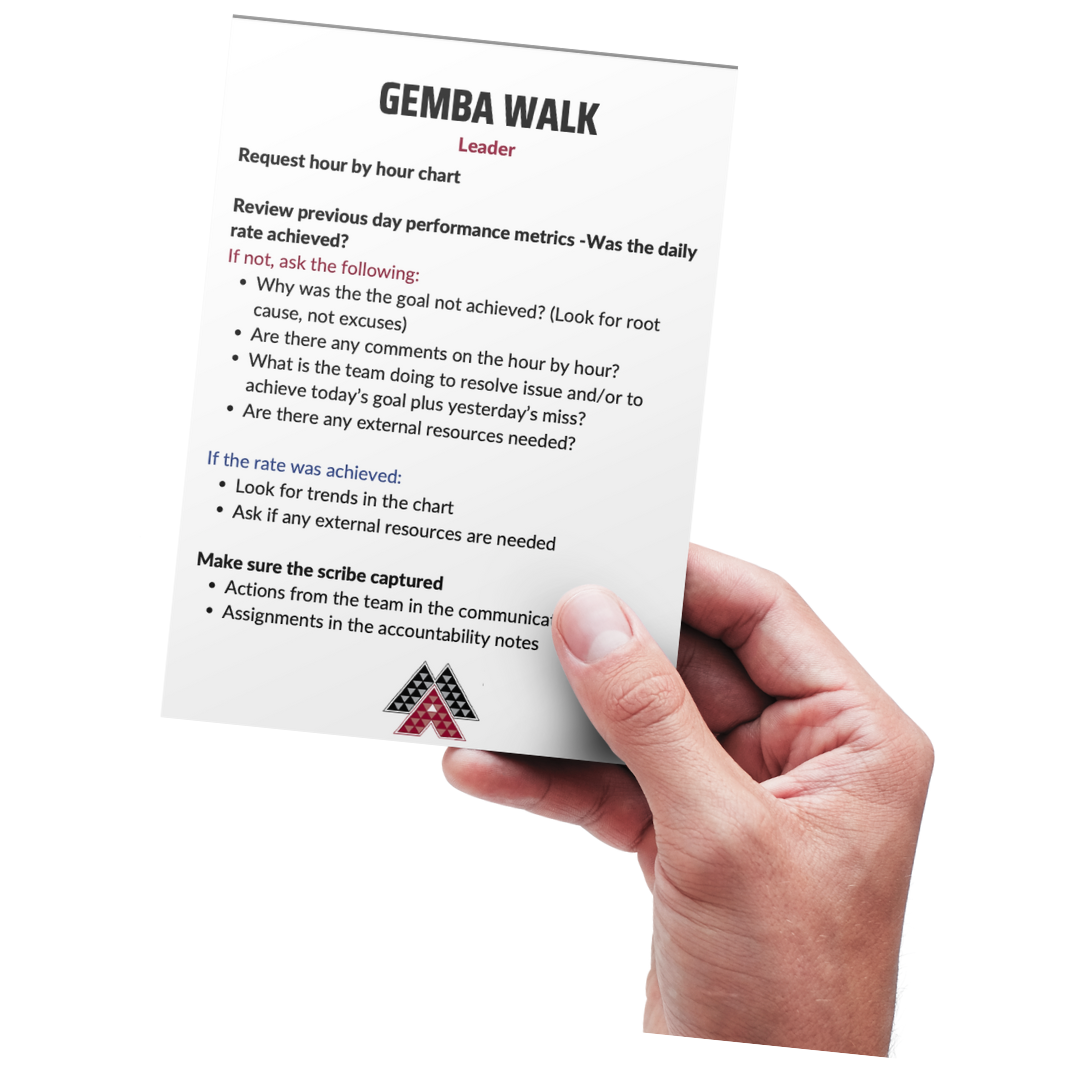

Gemba Walks

An in-depth shared understanding of a problem requires direct observation where the work is done – the Gemba. In this experiential workshop you will learn to use Gemba Walks to calibrate with your team so that you don’t become disconnected with issues on the floor and loose track of what resources are needed to improve performance.

Topics and Tools Learned Include:

- Define the Sr. Lean Practitioner Model

- Learn the types and purposes of a Gemba Walk

- Understand the pro’s and potential pitfalls of each type

- Understand how Gemba Walks are a key process in the MDI management system

- Outline the resources needed to be successful

- Develop an outline and practice your own Gemba Walk

Toyota Kata Coaching

Succeed as a team by learning how to coach problem solvers. Toyota Kata Coaching will help you develop people by promoting behavior that is best suited to help individuals use lean improvement techniques. In this experiential workshop individuals will learn a practical way to be a better coach, reach improvement outcomes with their team, and ensure all coaching in their company uses a repeatable framework.

Topics and Tools Learned Include:

- Define the Sr. Lean Practitioner Model

- The Kata Coaching Cycle and Structure

- The 5 Toyota Kata coaching questions

- How coaching systems guide behavior and create culture

- How to apply the practical coaching tools provided

Daily Accountability with Tiered Huddles

Allow for problems to be escalated, strategy to be deployed and accountability of both to be shared by all. In this experiential workshop you will develop accountability systems that include communication that supports the problem-solving process. This daily management system is built on a tier structure with practices, tools and behaviors that address organizational issues in order to sustain your team’s success.

Tools and Topics Learned Include:

- Define the Sr. Lean Practitioner Model

- Understand the purpose and benefits of a tiered huddle system

- Create a plan with resources to implement a tiered huddle system

- Develop a way to know if your team is following the system

- Incorporate a consistent means of corrective action

- Understand when and how to incorporate improvement tools

- Synchronize all four tiers of a tired huddle system

Gaining Buy-In for Lean

You know the basic continuous improvement tools. But, how do you use them to effectively transform the company? You need to know how to start, how much to tackle at once, who you need to involve, what results to expect, and what kind of resistance you will encounter.

Tools and Topics Learned Include:

- Change leadership best practices

- Realistic implementation strategies

- Execution planning

- Education and communication plans

- Overcoming resistance and biases

+ PROJECTS, TESTS, AND COACHING

Certification Project: All certification applicants are required to demonstrate their ability to apply what they learn by completing a project. This project must include positive measurable results that benefit the company.

Certification Coaching: All certification applicants are required to complete a Learning to Solve Problems coaching session. During coaching, you will learn how to be successful from project set-up to completion, recognize and mitigate bias, objectively define problems, learn where, how and when to access resources, and apply the Project Template as a project management tool.

MEET A FEW OF OUR

EXPERIENCED INSTRUCTORS

Sam Wagner

Sam Wagner has led continuous improvement, quality, and manufacturing teams in the Aerospace, Construction, and Plastics industries for more than 20 years.

Michael Muilenburg

Michael Muilenburg, is the Director of Operational Technology and Strategic Planning for the Film and Materials, Technology, and Engineering division at 3M.

Matt Kanz

Matt Kanz is the Senior Vice President of Human Resources for Jack Link’s Protein Snacks. He supports a global network of locations, feeding team members wild side through sustainable change.

Ron Mrocek

Ron Mrocek is the Director of Operations for the nVent Anoka facility. He has held positions in Lean, Materials and Operations with over 18 years of Lean Manufacturing experience.

THE PROCESS TO BECOME CERTIFIED

-

Step 1

Step 1

Enroll in Certification

-

Step 2

Step 2

Complete training

-

Step 3

Step 3

Apply what you learn

-

Step 4

Step 4

Get Better Results

Select a format then

Enroll in a Certification

Live Online

Starts TBA

Members $2,950

Non-members $3,450

In-Person

Starts TBA

Members $2,950

Non-members $3,450

Custom

We customize training to fit your team needs, timeline, and improvement plans.

Frequently Asked Questions

What is the time commitment for the certification?

Workshops, project, and final presentation may be completed in 6-8 months

Who is this certification for?

Operations, Engineering, Supply Chain and Lean Managers

What happens if I miss a class?

We recommend attending the next available workshop

What types of projects will participants complete?

Click here to view a real-world project