On-Demand Webinars

Fresh perspectives on leadership & operational excellence from experienced peers

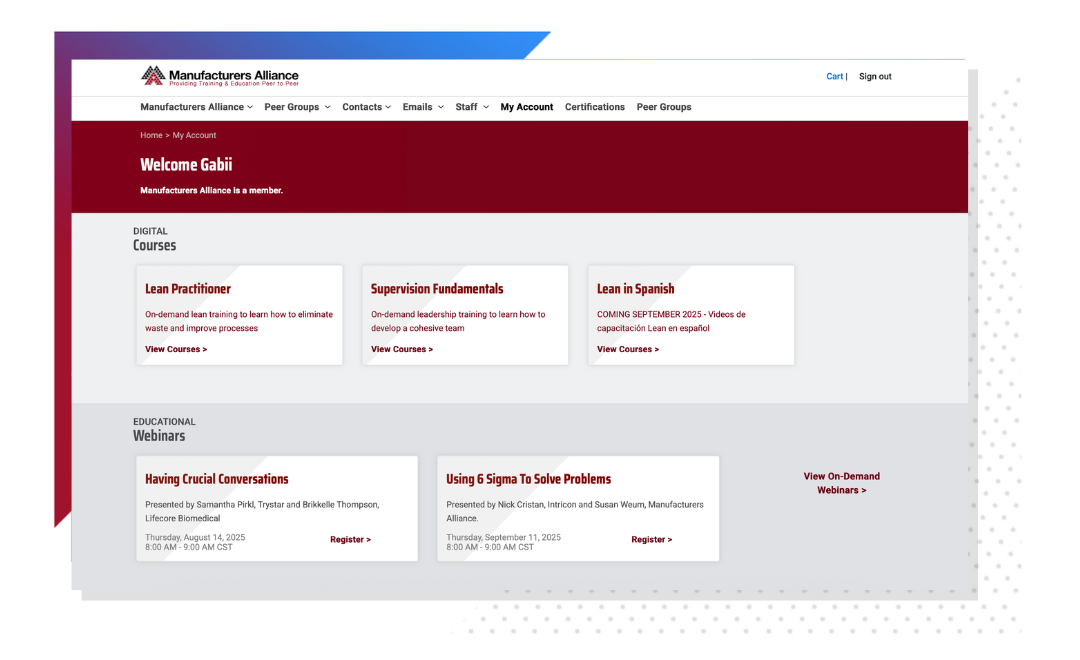

Now available in your My Account section

On-Demand Webinars Have a New Home

We’ve moved all on-demand webinars to the My Account section of our website for easier access. Simply log in, click My Account, and find your webinars in one convenient place—ready for you anytime.